The miners take turns chopping the coalface. All around us a jury-rigged jumble of tree trunks is wedged against the tunnel’s ceiling, our only protection from being crushed by the five hundred meters of rock between here and the floor of the northern Afghan desert. My claustrophobia mounts with every chunk of coal that dings off my plastic helmet. One miner crouches in the access shaft and shovels coal into an iron railcar. My headlamp catches his face, and I see his teeth are flecked with black. His wiry muscles are straining with the effort, but he works fast. The afternoon shift divides a two-dollar bonus for every tonne of coal they haul.

The crew is a half-hour into the afternoon shift, and they’re already filthy. Sweat mixed with coal dust trickles in rivulets down their bare backs. Superfine particles of coal swirl through the beams of their lamps. No one wears a mask; everyone breathes the black mist. The miners work down here, eight hours a day, for next to nothing—about a hundred dollars a month. And the statistics show they’ll spend ten percent of that income on petty bribes to the Afghan government.

The whole of the Karkara coalmine runs on a budget of only four hundred thousand dollars a year, less than a sixth of what director Abdel Munir says he needs to hire a full complement of workers and to bring the mine up to international safety standards. Not that anyone from the Afghan Ministry of Mines comes to check up on the mine’s safety conditions, or monitor its environmental practices. “The only time we see the government is when they come to audit us,” Abdel Munir told me.

If you flew over Karkara, you would see a giant slagheap spilling down a hill and off into the desert, rusted machines scattered amid the ruins of concrete buildings. You would see sheep grazing and chickens pecking. You might think the mine was long abandoned and suppose that Afghanistan had given up on its underground wealth when Zahir Shah was king. You might also imagine that Afghanistan doesn’t have much to offer the world in terms of mineral resources.

You would be wrong.

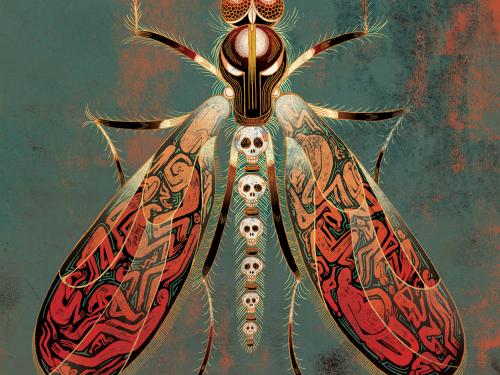

In fact, the scale of Afghanistan’s mineral riches became cause for heated international debate in June 2010, when the New York Times reported on a Pentagon-sponsored study claiming that Afghanistan’s rock is lined with at least $1 trillion in mineral deposits. The Times described the deposits as “previously unknown” and estimated their quantity sufficient that “Afghanistan could eventually be transformed into one of the most important mining centers in the world.” It was a flash of hope at a bleak time. Afghanistan’s mountain chains and vast deserts, created by the geological rumblings of the Triassic and Cretaceous periods, seemed for a moment less obstacles to troops and havens for terrorists than warehouses lined with copper, iron, and lithium, and studded with emeralds, rubies, tourmalines, and lapis lazuli.

A frenzy of calculations and opinions flooded world media, speculating that mining might win the war and pay for rebuilding along the way. The country’s biggest proven reserves—the Aynak copper vein in Logar Province and the Hajigak iron ore deposit in Bamiyan—are worth an estimated $694 billion. Development of those two sites alone could generate more than thirty thousand jobs and a billion dollars of yearly revenue for the Afghan government. It could also stimulate a flurry of infrastructure projects like roads, railways, and power plants, which would have a national economic impact far beyond the mines.

In reality, the Pentagon team, led by US Deputy Under Secretary of Defense Paul Brinkley, didn’t discover much that was new at all. Afghanistan’s rich gemstone seams had been famous for millennia—since the Pharaohs decorated their sarcophagi with scarabs made from Afghan lapis—and the big money deposits at Aynak and Hajigak had been known at least since before the Soviet occupation. The World Bank, USAID, the US Geological Survey, and the British Geological Survey, among others, have been helping the Afghan Ministry of Mines rebuild since the fall of the Taliban, guiding the ministry’s transition from shabby state-owned mining industry to a future facilitator and regulator of large-scale global investment.

But it didn’t take long for skeptics to accuse the Obama administration of trying to create excuses to remain in Afghanistan. Critics pointed out that President Hamid Karzai had been a feckless steward of the global aid pouring into the country; it was difficult to see how Afghanistan’s mineral wealth would escape the grasp of greedy ministers, and it was all too easy to imagine giant mining operations dredging a path of environmental disaster across the country. Still others questioned US motives for portraying itself as an investor instead of occupier. After all, hadn’t the Bush Administration officials predicted that Iraqi oil wealth would pay for both the war and reconstruction?

When I arrive in Kabul in mid-July, my first stop is the Afghan Geological Survey (AGS), where I meet with Darryl Thorburn, a sixty-six-year-old Kiwi mining engineer who came to Afghanistan in 2007 after retiring from the directorship of Crown Minerals, New Zealand’s national mining agency. Thorburn is part of a team of expatriates advising the AGS and the Ministry of Mines as part of the World Bank’s Program Management Unit (PMU), commissioned in 2006 with a five-year budget of $40 million to help restructure the country’s mining agencies. The PMU’s role, as Thorburn understands it, is to “harden up” the Ministry of Mines and the AGS in anticipation of a massive surge in mineral development—a continuation of prior World Bank assistance in the drafting of the 2005 National Minerals Law, designed to protect Afghanistan from one-way foreign exploitation and protect investors from the vacillations of Afghanistan’s mercurial government. “It’s their resources, their money,” he says. “Mineral deposits aren’t just minerals. If done properly, they will fund development.”

Shaggy-haired and grandfatherly with kind blue eyes behind rectangular glasses, Thorburn takes me on a tour of a huge computer generated map on the wall of his office. The map resembles a wildly colorful ocean coral, or an exotic rainforest leaf, with fanning plumes of deep purple and burgundy, sulfurous ochre, and turquoise. The colors correspond to a legend of esoteric mining designations: schists and intrusions of gabbros, diorites, basalts, limestones, quartzites, carbonatites, and rhyolite. Thorburn prattles on for a few minutes in a pidgin of English and geological jargon, and finally I confess that I have no idea what the hell he’s talking about.

I ask him to point out the Aynak and Hajigak deposits. On the map, Aynak is a scatter-plot of schoolbus-colored squares southwest of Kabul. Hajigak is a cluster of yellow stars inside brown circles that remind me of old fighter plane insignia. Much of Thorburn’s work has focused on improving maps like the one we’re looking at. With PMU help, the AGS is busy establishing a mine inspection system and building a comprehensive mining cadastre based on GIS technology, a kind of super map that will detail all potential and known mineral and hydrocarbon deposits and also track the locations of forthcoming exploration and extraction permits. The cadastre will be critical to the transparent and efficient management of Afghanistan’s mining industry—and the fact that the country still doesn’t have one says a lot about its present readiness to take on foreign investors.

Six months before the Brinkley team filled the airwaves with news of Afghanistan’s $1 trillion mineral reserves, the incoming Minister of Mines—a thirty-eight- year-old reformer named Wahidullah Shahrani—asked Thorburn and his group to provide an estimate of the total value of Afghanistan’s minerals and hydrocarbons. They arrived at an even higher figure than the Pentagon: $1–2 trillion of potential value, based on volume and tonnage estimates and current global prices. “Shahrani is an accountant, so we tried to present the information to him in a way that an accountant would understand, you know, what’s the size of the prize?” But Thorburn told the minister to forget about the numbers. “It might cost three times that to get it all out of the ground, and therefore it might stay in the ground. The value is nil until it’s out of the ground.”

The PMU has pressed the ministry to stay focused on capacity building, so that a solid business plan and streamlined management systems are fully in place when the country is finally safe enough to court large-scale foreign investment. As one would expect of a geologist, Thorburn seems comfortable with long timelines. Talking about the ministry’s decision last year to postpone the tender for the Hajigak iron ore deposit, he says, “This thing has been sitting around for a hundred million years. Better to let it sit for a few more years and do it properly, rather than rush into it and mishandle it. We’re here to win the war, not just the battle.”

In the six years since the Ministry of Mines began putting its house in order, it has signed only one international contract—a $2.7 billion deal with the Chinese MCC-Jiangxi Copper Consortium for development of the Aynak deposit. The National Minerals Law provides the basis for the contractual regulations. Thorburn says the contract’s conditions would “make the Americans and Canadians quite satisfied,” if the mine were in their own countries. It’s critical, he explains, to ensure that Afghanistan’s extensive mineral wealth does not devolve into a “resource curse,” a term used by economists to describe the disastrous environmental and economic impact of exploitative resource extraction in vulnerable, shoddily-governed developing countries. MCC-Jiangxi also operates in Sub-Saharan Africa, where mining and oil extraction have stripped countries of the resources necessary for their own industrial development. Chinese money has also propped up brutal strongmen, encouraged violent conflict, and sown ecological ruin, cutting locals out of the value chain as a matter of policy. Thorburn doesn’t shy from the truth. “MCC’s reputation isn’t good in Africa,” he concedes, “but that’s partly because there aren’t good contracts there.”

The Aynak contract binds MCC to a monumental shopping list of infrastructure projects. Before they haul off an ounce of Aynak’s 240 million tonnes of copper, the Chinese will have to build asphalt roads linking Logar north to Kabul and west to the Kandahar Highway in Wardak. They will have to build a four hundred megawatt power station, which will supply half its output to copper refineries in Logar. They will build the refineries, too, which will generate more jobs inside Afghanistan and make its copper a value-added export. The Chinese will build power lines and transfer stations to channel the remaining two hundred megawatts to the Afghan grid. Today, neighboring countries supply the Afghan grid with 230 out of the 231 million kilowatt hours it consumes. To fuel electricity production, the Chinese will have to assist in the development of Afghanistan’s coal and hydropower resources. Finally, and probably most important of all—the one stipulation that distinguishes Aynak from Chinese “infrastructure for resources” swaps in places like Congo—MCC-Jiangxi will draw a hundred percent of unskilled labor required for infrastructure-building and mining operations from the Afghan population. They will then set up training programs so that future generations of Afghans can take over skilled jobs at Aynak from the Chinese. They’re already building a new town to house them.

Aynak must be worth it; otherwise the Chinese wouldn’t go to so much trouble.

I gaze into Thorburn’s coral map, devoid of place names, awash with colors and arcane geological symbols. This map is beautiful. Part of me wants to trust his experience and measured confidence. He has worked inside the Afghan government for three years—no American general can say that—and he must know its limitations. I ask him to put a figure on his optimism. He pauses for a moment, looking down at his hands. “I’d give it about a seventy-five percent chance,” he says. “As long as the security situation holds up.”

Mohammad Ali’s four-wheel drive Toyota minibus blows through the Jalrez Valley, famous all over Afghanistan for its apples—and, among the American troops in Wardak, for the size of its IEDs. I slink low in the backseat and drape my scarf over my pakol. Mohammad Ali looks straight ahead and drives as fast as the road will allow. He swerves onto a detour through a bean field near an Afghan National Army post. I glance left out the window and see a giant patch of dirt and gravel where the road must have been before the IED. I catch Mohammad Ali’s eyes in the rearview mirror. I say shit, and he mouths something too—the same thing, I’m sure. The minibus runs into the old world at the end of the Jalrez, where the asphalt runs out, and we start our long journey on the unpaved road to Bamiyan. Outside our windows, the faces of the villagers have lost their sharpness, the beards are thinner, and the women watch us as we go by, their hair wrapped in colorful hijabs. We are in the Hazarajat, the Central Highland territory of the Hazaras, Asian-faced descendants of Genghis Khan’s Mongol hordes.

At long last, we crest a hill, and Mohammad Ali lurches to a stop, takes out his phone, and holds it up to see if there’s a signal. He looks back at me in the rearview mirror. “Assad,” he says, nodding at me. Assad is my contact in Bamiyan, a kid who spent a year of high school in San Antonio and arranged for my ride. Mohammad Ali hands the phone back across the benches to me, where I’m still slouched down, peeking out from underneath my scarf. “Elliott,” Assad laughs over the phone. “He says it’s okay now. The bad area is behind you.” I look up and catch Mohammad Ali grinning. I pull my scarf down around my neck and shoot up in my seat, breathing for the first time in hours.

We cross into a steep-walled mountain pass where the cliffs are banded with deep reds and oranges. It’s Hajigak. These rusty hills, a hundred miles west of Kabul, contain almost two billion tonnes of high-test iron ore, worth an estimated $420 billion. The canyon walls to our left and right are scored with goat trails inches wide, and there are kids on them, bounding behind files of sheep and goats, whacking them with switches. Clusters of qalats occasionally dot the hills. There is no electricity here. No cars or tractors parked beside the compounds. Bamiyan is a place that time and the Afghan government have consigned to history. The road is barely wider than the van where the mountains stretch out and we begin our descent into the wide Bamiyan Valley. We’re hundreds of feet above the floor, and the edge pulls us like a tractor beam. Mohammad Ali folds the side view mirror in so minibuses can edge past in the other direction; he reaches out and shakes hands with the other drivers.

A thousand miles of valleys linked east to west mark the seam of the Farad and Tajik blocks, through which the Silk Road once passed, leaving scores of crumbling caravanserais behind, and little else but ruins and eye-popping natural wonders. Band-e-Amir, a huge volcanic pit filled with brilliant azure water, is two hours from the center of Bamiyan. The holes where the giant Buddhas once stood, before the Taliban blew them from the cliffs in 2000, flank the city of Bamiyan. And there are the ghastly ruins of Shar-i-Gholghola—the City of Screams—where Mongol horsemen slaughtered every living thing in the thirteenth century. At Sheish Pol, where I register at a police checkpoint, I look out the window and see another of Bamiyan’s fossilized towns, the ancient Red City, hanging in ruins on the cliffs to the south. On the other side, two-dozen workers with picks and shovels are knocking away at the road north to Parwan Province. I write my name and passport number on the registry and scan down the list of other foreigners who have come by the Hajigak road. There are a few, weeks apart. No Americans.

At the old campus of Bamiyan University—a two-story concrete block painted white with blue trimming, one of the only modern structures in town—I meet up with thirty-eight-year-old Hassan Malistani. His pencil mustache and rimless glasses match his tall, rail-thin frame and skeletal face. He’s a native Bamiyani, but he spends most of the year at Bonne University in Germany, where he’s one year into doctoral research on the Hajigak iron ore deposit. He’s got a drawer full of samples ready to schlep back to Bonne from this trip. The prospective site for the industrial mine is an hour’s walk into the mountains, but, Malistani says, “you can drive to Hajigak and pick these up from the side of the road. It’s everywhere.” I turn a heavy sample over in my hands. It’s cold, covered in what I guess must be rust. The Afghan Geological Survey rates the Hajigak ore at 62 percent Fe, but Malistani’s testing in Bonne rates it at 65 percent or higher—an exceptionally high grade. There’s absolutely no doubt the ore is there, Malistani says, and probably more than anyone knows. A Soviet team surveying Hajigak in the sixties drilled two hundred meters into the ground and failed to tap the bottom of the deposit, and it ranges over twelve miles of the Baba Mountains. “It’s enough to keep people digging for a thousand years,” Malistani says.

The best part of Hajigak, he says, is that the ore is close to the surface, which makes it amenable to open-pit mining—easier, less expensive, and less dangerous than underground mining. The only problem he foresees is the Afghan government. “This deposit is very large. The government of Afghanistan is not able to explore it.” He emphasizes, “We need international companies.”

Like Darryl Thorburn, Malistani believes powerfully in the potential of Afghanistan’s mining industry to transform the country, and he pleads for patience and caution on the part of the government. He worries that “companies that are interested now want conditions that are not good for Afghanistan.” In particular, he thinks a twenty percent share for the government of all exported minerals is exploitative, not enough to make a difference for the Afghan people. He also doesn’t trust the government to put mineral revenues to good use. He thinks huge contracts with single investors—like the Aynak contract with MCC-Jiangxi—open the door too wide for corrupt businessmen and government officials, National Minerals Law or no. “My opinion is that it’s better to postpone the project until we have infrastructure and security together.”

As it stands, that infrastructure is sorely lacking. Bamiyan—near the bottom on Afghanistan’s list of poorest provinces—has almost no cars. Most of the population walks. There is almost no electricity in the province either, none from the national grid anyway. What little power there is comes from generators and a few donor-supplied mini-hydroelectric turbines. Bamiyan is cut off from the national political grid, too. In the entire province, there is only one paved road. It goes from the city center up to the airstrip and wraps around to the new government center, where Afghanistan’s first female governor, Habiba Surabi, has her office.

Surabi is one of the only women I’ve ever spoken to in Afghanistan, and definitely the only Afghan woman I’ve shaken hands with. She’s middle-aged and motherly in her white hijab and grey skirt and jacket, but she’s tack sharp. I ask if she thinks Kabul neglects Bamiyan. She weighs her words carefully. “Bamiyan people are very poor,” she says, “but they’re sitting on top of a treasure, in mines, in history.” She says she hopes the central government will expand aid to Bamiyan in the interest of making it attractive to mining investors and to bring tourists to Band-e-Amir, Afghanistan’s first national park. (There’s a $63 million project underway to pave the road between Bamiyan city and Band-e-Amir.) Two northward roads already in the works will link Bamiyan to the Salang highway—one to Parwan Province providing easy access to Kabul, and another to Baghlan Province allowing northbound trucks to bypass the Salang Tunnel on the way to the railhead at Mazar-e-Sharif. The Hajigak road is also open for bids. But the tender has been out for four years, and no offers have come in. No one is ready to risk a major road project in the Pashtun villages between the Jalrez and the Hazarajat.

If Bamiyan is the safest province in Afghanistan, investors understand: the enemies are at the gates. Just the week before, insurgents killed six construction workers and kidnapped the district attorney in Tala Barfak, on the border of Baghlan and Bamiyan. The workers were laying asphalt down on one of the road projects Surabi told me about. A few days later, insurgents from Baghlan traveled deep into Bamiyan to ambush a soft-armored convoy from the Kiwi-led Provincial Reconstruction Team. In May, nomadic Kuchi Pashtuns suspected of links to the Taliban raided Hazara villages in eastern Wardak for a week, burning homes, murdering six people and displacing hundreds of families.

Before foreign companies can haul billions of tonnes of minerals out of Afghanistan, the country will need a colossal infrastructure makeover. Nothing says high volume, high tonnage transport like railroad, but until this year Afghanistan didn’t have a single meter of track. But now the Asian Development Bank is paying the Uzbekistan Railway Forces (UTY) $130 million to build Afghanistan’s first rail spur, linking Mazar-e-Sharif, the country’s northern commercial hub, with the southern Uzbek city of Termiz.

In Kabul, I look at a map of potential spurs with Valeri Tian, a Kyrgyz engineer at the ADB headquarters office who manages the railway portfolio and the ADB-managed feasibility study on the national railway system. “From the connectivity point of view, for Central Asia, it’s really quite amazing,” Tian says. Coming from Kyrgyzstan, he knows something about the difficulties of growing an economy in a landlocked country. He points to prospective spurs to Pakistan and Iran, where cargo coming out of Afghanistan could reach container ships docked in Persian Gulf and Indian Ocean ports. From there, the world. Tian thinks it would take as much as $6 billion to complete a national rail circuit—more than donors could manage alone, and that only when Afghanistan is safe. But my mind reels at the possibilities: a new Silk Road, new energy corridors, and uninhibited cross-border commerce leading to a Central Asian co-prosperity sphere. I have to see this.

Even though the northbound highway to Mazar-e-Sharif is asphalted, it still takes nine hours to make the 250-mile trip from Kabul. It’s midafternoon when our tires finally thump across the railroad tracks at Nayzabad, where the line coming east from Mazar takes a smooth turn north to Hayratan on the Uzbek border. Uzbek laborers are hammering wooden beams on the roof of a signal station at the junction, wearing blue jumpsuits with orange accents. The railroad is real, I say to myself. They’re really doing it. In the wide-open desert valley between Nayzabad and Mazar, I can see the raised track shooting all the way to the hazy horizon. Close to Uzbekistan and comparatively safe, Mazar-e-Sharif is a trucking boomtown. Warehouses and container yards fill the roadside on the approach to town. Someday they might hold shipments of refined ore on the way to the factories of the world. All the Afghans have to do is figure out how to get the ore out of the ground.

It’s five in the morning when we pile out of a Russian-made jeep beside the Panjshir River in Dashtari Wat. Commander Jalaluddin, the leader of our ragtag gang, jumps down the bank to fill a yellow jerry can with river water, and then we’re off. My guides wear shalwar kamees and vests, pakols on their heads and cheap high-tops on their feet; they bound ahead like goats up the steep, shale-strewn path. A day earlier, at the Afghan Ministry of Mines office in the Panjshir Valley, I had asked for a guide to lead me to the emerald mines high in the Hindu Kush. The local director, Abdel Habib, a former mujahideen fighter who had battled the Soviets in the Panjshir, instead offered me five—with Jalaluddin in charge. Jalaluddin is sinewy, with a salt-and-pepper beard and quick smile. He looks sixty but thinks he might be forty-three or forty-four. Fifteen years my senior. Still, only minutes into our climb, my sea-level lungs are bursting, and he and his men turn occasionally to see if I’m still with them.

On the slope, two passing shepherd boys see me struggling and strap my bag to the back of their donkey, tying it to saddlebags loaded with rice and ghee. Without the weight, I can finally soak in the scenery—lush alpine meadows, lavender fields, peaks layered on the horizon. I pause, panting, to survey the receding valley and measure our progress against the black, snow-capped mountains to the west. The valley is already a green speck under a carpet of haze.

After an hour of climbing, the boys lead their donkey off on another trail, and I’m stuck with my bag again. When I catch up, my guides are sitting down eating cakes. They toss the wrappers into the wind. Jalaluddin smiles at me from his perch and points over his shoulder at a pair of black holes on a rock ledge a hundred meters farther up the mountain. “There’s the mine,” he says. “You can take your picture now.”

But there are no workers. Come to find out, this mine is closed for the summer. During these warm months, the miners stay above four thousand meters, working in places that are too high, too cold, and too hard to reach in winter, even for them; this particular mine is open only in the early spring. I press to go higher.

My translator Nur Rahman listens as my guides bicker in Dari, summarizing their exchange. “They say commander”—Abdel Habib, that is—“told them take you this high and bring you down. They don’t want to take you higher. Too dangerous for you.”

An explosion halts the argument, and all of the men look up the peaks.

“They’re working up there?” I ask. Jalaluddin nods.

“Tell them I’ll pay them to take me up.”

The fat one looks at me. He was as slow as me climbing the mountain. “Abdel Habib tell us to bring you this far,” he says, “and we do it because it is our duty as Muslim and you are guest in our country. We never do this for money.”

“How much you pay?” Nur Rahman asks.

“Seven hundred afs,” I reply. About sixteen dollars apiece.

Nur Rahman laughs. “They say they all give you seven hundred afs to go back down and let them go home.”

They squabble in Dari while I lie back on my pack and close my eyes, pulling in lungfuls of cool mountain air. Nur Rahman taps me. Jalaluddin is standing up, tilting his head toward the peaks. “Okay,” he says. “We go.”

At the entrance to the dormant mine Jalaluddin picks up a handful of low quality emeralds. They’re a milky, pale turquoise color, embedded in chunks of yellowish limestone, trash as far as the miners are concerned. “No good,” he says, dropping them at his feet.

We march on. The sun is hot overhead, shade harder to find, but on distant peaks, snow lingers in the shadows. The men are far ahead, crouched under an overhang, waiting. I’m panting, bent over, hands on my knees. I look at my watch. We’ve been hiking for almost six hours. High up the arête, past two or three more snowfields, I can make out a tiny beige rectangle perched on a swatch of green.

“Is that the miners’ camp?” I ask.

“Yes,” Jalaluddin answers. “The low camp.”

Jalaluddin cups his ears, motions for me to do the same. I can hear the miners’ drill buzzing. The valley thunders and we see a plume of dust rising from a knobby peak. A black speck moves into the dust. A miner. Jalaluddin shouts, “Haallllloooooo,” and a response comes back from the small band of miners, filling the mountains with echoes. We slog up to the camp and crawl inside their stuffy, cramped tent. After a break, Jalaluddin, Nur Rahman, and I leave the others behind, dozing, to make our summit push. The fat man grins and shakes his head as I crouch out of the tent.

Jalaluddin reaches the miners in no time. Nur Rahman isn’t far behind. I am very far behind. Finally, I pull myself up to the band of dirt where three men are working. One—a sharp-nosed twenty-two-year-old named Izhak—is Jalaluddin’s son. Jalaluddin, I discover, is actually part owner of the prospect, and his older brother Saif, who could be his twin, is crouching in a car-sized hole chopping away with a crowbar. It’s a new mine, just opened this year, and Jalaluddin is interested to see how it’s going. He grabs a chisel and pitches in.

The techniques are primitive: the miners bore two-foot holes in the rock with a drill, then fill the holes with explosive powder. The blasts allow them to pry off blocks of rock with chisels, hammers, and crowbars. Sifting through the chunks, the miners look for soft limestone striations that indicate a high likelihood of emeralds. They are true prospectors. Each man shares the risk—either with his labor or his capital, or both—working only on the hope that he’ll get a share of the find. They are happy if they make two or three thousand dollars in a season, which is enough to sustain their families until the next year.

A scowling miner named Ali tells me his team once found a half million dollars worth of emeralds in one summer. But the men also say that a couple of years ago their team went bust. So far this summer they’ve found nothing. They know they damage a lot of good gems with their blasting, but they don’t know any other way.

The night before, in Abdel Habib’s cushion-lined sitting room, he reminisced about the good old days in the eighties and nineties, when Ahmed Shah Massoud ruled the Panjshir. Massoud, the famous Tajik mujahideen leader whose photo still adorns more billboards than Karzai’s in the north, supported the miners with explosives and other materials smuggled in from Pakistan and Tajikistan. His men also helped smuggle gems out of the country as they crossed the border to pick up weapons and ammunition. Massoud’s army would take a cut of about ten percent—less than the current Afghan government’s fifteen percent—and reinvest it in the fight against the Soviets, Abdel Habib said. “Now if we tried to bring in explosives, we’d get arrested.” Kabul keeps a tight and understandable grip on explosives, but Abdel Habib’s requests for supplies on behalf of the Panjshiri miners have gone unanswered.

Habib said that during the Massoud era seventy percent of the population in Panjshir’s emerald villages—Dashtari Wat, Safidchir, and Khenj—made their living from the small, artisanal operations. Now the miners make explosives from soap and ammonium nitrate, just like Taliban insurgents, and they can’t produce nearly enough to keep the mines open. Twenty years ago there were some two thousand men working in the mines above Panjshir, Abdel Habib said. Today, there might be twenty or thirty open mines tended by perhaps two hundred miners.

Up on the precipice, I ask the men if they’ve heard about the government’s plan to revamp the Afghan mining industry. They haven’t. I ask if they’ve ever had a visit from a mine safety inspection team. They look confused. Safety inspection? Saif, Jalaluddin’s brother, says, “If the government supported us, we would go fifty-fifty with them.” But that seems like a stretch given that no one is exactly sure what Abdel Habib, as director of the local ministry, actually does with the emeralds after buying them from Jalaluddin.

The World Bank estimates total annual trade in uncut Afghan gemstones at about $2.75. million. The Ministry of Mines does not issue permits for gemstone mining, not yet anyway, and operations like Jalaluddin’s and Saif’s are semi-legal—not officially criminal, but not officially sanctioned either. Abdel Habib claims the miners sell their emeralds to Kabuli merchants at auction, and that the Ministry of Mines takes its cut from there. But I suspect that Abdel Habib probably just cuts the Ministry out altogether. Since most of the emeralds found in the Panjshir still go to Pakistan for cutting and polishing, it’s entirely possible that the miners simply pass their goods off to smugglers almost as soon as they emerge from the earth.

We walk down from the mountain as evening comes on. Thunder crashes in the distance as we begin our descent. We stumble down the rocky paths, through the snowfields. My legs are rubbery but my lungs swell as the air thickens. By the time we reach Dashtari Wat, it’s dark and pouring and the village is dead. There is no mobile reception and no landlines. No chance of calling Abdel Habib to pick us up. Jalaluddin takes us into his home, a large mud-brick compound next to the village spring. His son brings in a tray of tea, then stacks of naan. We eat a stew of salted cheese and onions, then Nur Rahman prays for a long time; he says he likes to take his time, not to rush it. Jalaluddin turns off the battery-powered lamp, brings me a blanket, and ducks out of the door. I’m beyond exhausted, but my imagination races with the stunning alpine scenery of the day. Hajigak is at the same altitude as the emerald mines, I think to myself. Could anyone industrialize mining at such a height? I stare into the blackness and drift off, damp in my clothes, listening to the sound of rain on the windowsill.

Pul-e-Khumri is a strip of one-story brick buildings painted in grime from the steady spatter of jingle trucks clanking their way between Kabul and Mazar-e-Sharif. Donkey carts loaded with watermelons and apricots clomp along the gutters. A steady shower of sparks comes from the roadsides as men and boys toil in metalsmith shops, grinding shovel blades and hammering together wheelbarrows. We turn off the main road and head east, toward Karkara, home of one of Afghanistan’s only industrial mines. The road runs parallel to a dry riverbed where kids scavenge rubbish from amid the rocks. Near a giant cement plant we come to a scar in the earth where floods swept the asphalt road into the Salang River a few weeks ago. We rattle for an hour through a monotonous landscape, and I count six Soviet armored personnel carriers scattered in frozen formation on the rolling hills. Eventually we come to a coal car atop an iron stand. Below it a sign with crossed miners’ picks points the way to Karkara.

A fence improvised from coal cars marks off the garden of the mine’s office. Inside, the director, Abdel Munir, who began his career at Karkara as a fresh engineer thirty-two years ago, bathes in the breeze of an air conditioner, his desk arranged with stacks of crisp paper and a tiny Afghan flag. A portrait of Hamid Karzai hangs on the wall behind him. Abdel Munir’s hair is greased over a bald spot, his beard neatly trimmed on his plump face. He wears one of those gold-plated digital watches with the stretchy band and gold-rimmed glasses. He strikes me as a humble man. He keeps a simple bed in the back room, and he tells me he often sleeps here to avoid the spine-rattling ride back to Pul-e-Khumri. A chai boy brings tea and a plate of pistachios, raisins, and dried chickpeas. Abdel Munir tells me that shepherd boys discovered the mine in 1939, when they made their fire pit with strange black rocks and noticed the rocks burned longer than the wood. Not long after, the government swept in and nationalized the coal deposit, and it stayed that way for six decades.

When the new Ministry of Mines privatized the mine at Karkara in 2002, Abdel Munir’s parent company, Afghan Coal, won the contract to manage it and the cement factory we passed on the drive in. They agreed to pay $1 million for the mining rights, plus a tax of eight dollars per tonne of coal. “We pay that tax whether we are making money or not,” he says.

Munir punches on his calculator as we talk. Karkara is a cash sieve, he says. Afghan Coal turned a profit on the mine of only fifty thousand dollars last year; Karkara has lost seventy thousand dollars in the last three months alone. Munir is constantly frustrated by his company’s failure to improve production or invest in the mine. He explains that the cement factory is the company’s priority, and Afghan Coal is willing to run Karkara ragged as long as the cement plant gets enough coal. Karkara’s miners drag out only a hundred tonnes per day, and all of it goes to the cement factory, where it becomes part of the chemical mix that improves the cement’s bonding properties. There is no coal-generated electricity in Afghanistan, where what little electricity exists comes from village-level hydroelectric operations or is bought from neighboring countries. Abdel Munir thinks his men could more than double their current output if the company rehabilitated the mine’s infrastructure. His miners need a new generator, air compressors, a narrow gauge rail line, and a locomotive, plus masks and helmets that meet international safety standards. All of this, Abdel Munir tells me, would cost $2.5 million.

The company hasn’t purchased a new machine in forty-five years, and this becomes obvious when I see how coal is actually hauled up out of the ground. The pulley system that once dragged coal cars out of the mine died decades ago, and now the miners lower themselves in with a winch, two cars at a time. At age fifty-six, Abdel Munir has known some of the Karkara miners for more than half his life. He says Afghan Coal puts them in danger by understaffing the mine and refusing to pay for even the most basic safety measures, such as tunnel support structures and ventilation pumps. He barks into a radio occasionally. “Daoud? Ibrahim?” he yells, checking on his men. “I never relax until the men are out of the mine,” he says. Lunchtime—when the morning shift miners come out and the afternoon shift prepares to go down—is Abdel Munir’s favorite time of day.

In the afternoon I climb into a coal car and slide down into the blackness with the shift foreman, a stubble-faced, stout worker named Abdel Waseeh. He switches on his lamp and scans the arched roof for fallen support timbers. Our ride screeches to a halt at a junction where a locomotive used to pull cars along the shaft before it, too, joined the junkheap outside. Now the miners push the cars to the junction. I crouch down and scramble behind Abdel Waseeh, who slips gracefully through the tiny tunnel. I bonk my head on every rafter, cursing, trying to juggle my cameras and my archaic miner’s lamp. I take note of the lack of steel girders above our heads; the entire tunnel system is propped up by a crooked lattice of trees. A miner scampers toward us on all fours. He stops to reach up and shake hands with Abdel Waseeh. Slick with sweat and coated in black slime, he looks like some gremlin roused from the deep.

At the end of the shaft, four miners hack at the coalface with picks. They are shirtless, wearing only shorts and helmets. Showers of coal rain down on me as they chip at the black wall. They are all wiry, older men—the youngest is thirty-eight. They are mostly cheerful despite the conditions of their workplace. One strikes a fearsome warrior pose with his pick and squints as the beam of my lamp burns into his eyes. Mohammad Atta, the oldest at forty-eight, is “a very famous worker” in the words of Abdel Waseeh, legendary for the volume of coal he hauls. He swings at the coal in a fit of rage.

As the men work I try to take stock of their world. Support timbers are wedged with no discernible pattern against the walls and ceiling, and a small ventilation fan sucks some of the coal dust out to the shaft entrance. But much remains. My lamp burns a yellow line through a haze of dust, and soon I start coughing. I remember Abdel Munir telling me of an explosion of methane in the mine last year that killed one of his miners. A collapse this year trapped another who suffocated before his comrades could dig him out. There are safety rules here, but they’re Abdel Munir’s, not the government’s. The Ministry of Mines doesn’t have a mine safety inspection unit yet.

Earlier in the day, over a worker’s lunch of stewed lamb and rice, Abdel Munir had described his exasperation. The Soviets estimated the Karkara coal seam at nine to twelve million tonnes, but Karkara’s production levels haven’t increased since the seventies. One reason is that Afghan Coal won’t raise workers’ salaries. The two hundred ninety-one workers currently employed in the mines earn only about a hundred dollars a month. Abdel Munir thinks there’s more than enough coal down there to employ three thousand people, amass a fortune for the company, and fuel power plants across the country (for example, developing the Aynak deposit will require coal to fire the planned 400MW Chinese electric plant). If he had control of the budget, he would double salaries to attract more miners. “The contract says we should have four hundred and fifty workers here,” he says, “but no one wants to work so hard for so little.”

Abdel Munir says he’s written letter after letter to the company, hounding them to give him the workers and equipment he needs to bring Karkara’s wealth above ground, but the complaints fall on deaf ears. He thinks the government shafted Afghan Coal on the contract, but he remains hopeful, because pressure rising from the Ministry of Mines’ development plan might one day force the company to reevaluate its priorities.

The windows in the spokesman’s office at the Ministry of Mines look out on a surveillance blimp equipped with cameras that scan the city blocks below. Actually, there are no windows—no glass anyway. While I sit there, waiting for my appointment with the Minister, the spokesman, a doughy man with fat cheeks and greasy curls named Jawad Omer, flips between soap operas and a fuzzy game of cricket. In this dynamic age of the Ministry, he clearly has nothing to do.

I have come to see Minister Wahidullah Shahrani, but he flees the office for a meeting with Karzai and I get shunted off to Nasir Ahmed Durrani at the last minute. Durrani, a fifty-eight-year-old Pashtun from Logar Province, serves as the senior finance adviser to the minister. He describes the ministry’s transition from a state-owned mining agency to a facilitator of international investment, reading tediously from a printout, pausing between the bullet points. I tell him that I could just print off the press release myself, and ask if we can just talk. Afghanistan is about to open its multi-billion dollar Chinese mining operation—a giant project even in a developed country—and I want to know if they’re prepared to take on that kind of money. “What’s the total value of Afghanistan’s current mining operations?” I ask. “It’s difficult to say,” Durrani says. “We estimate that between six hundred to seven hundred tonnes of chromite are stolen every day.” He can’t put a figure on how much that’s worth. I press him again to give me an estimate of the current value of Afghanistan’s legal mining industry, but he can’t. At present, Afghanistan’s minerals are all abstract potential. Hopeful possibilities, but nothing more. And so are the railroad, the ambitious road projects, and, at the bottom of it all, the Afghan government.

“Do you have any concerns at all about whether or not the ministry’s plans will succeed?” I ask. “Really, I believe in the change to a market-based system,” he answers, testifying to an article of faith. “Really I don’t have any concerns.” This has been the bloodiest year of the Afghan fight yet, nearly five hundred foreign forces dead so far, more than two thousand Afghan civilians killed by IEDs alone—and the formerly southern-focused insurgency has metastasized around Kabul and all the way to the Uzbek, Iranian, and Tajik borders. What if the Americans pull out, as Barack Obama has promised they will as early as 2011? Durrani shakes his head, folds his hands on his crossed legs. “I don’t believe the Americans will leave,” he says. “The whole world is behind Afghanistan now. They will stay until Afghanistan is able to take care of its own responsibilities. I am optimistic.”

What he said, but wouldn’t say, is that Afghanistan and all its fantastic mining plans will crash and burn without foreign support. The extent of the investments needed to reach and exploit Afghanistan’s subterranean wealth is enormous, and nothing of the kind has ever been attempted. The Soviets knew well what lay beneath the earth—they pumped gas from Jowzjan Province throughout the war—but they could not stop fighting long enough to chase their mineral dreams. Beyond all the glittering potential, there is little to suggest that a nascent mining industry won’t fall prey to dirty officials or, worse, end up funding insurgent networks.

Still, Aynak and Hajigak alone could be enough to bring Afghanistan’s economy above ground, to transform the country utterly. The potential of those deposits is as solid as the block of iron ore I handled in Malistani’s office. And every Afghan sees it as their only hope. The fact of the matter is that Kabul is surrounded, the Taliban are waging a fierce campaign against NATO forces and the Afghan army all over the country, and the Afghan government is more in need of foreign military and financial support than ever. If the countries of the world decide to give up on the fight against the Taliban, and to give up on developing Afghanistan’s institutions, there won’t be any point in worrying about whether or not the Ministry of Mines can handle mineral investment. There won’t be any investment, and there won’t be any government. There would then be no sense worrying that mining might turn Afghanistan into another “resource cursed” humanitarian and environmental disaster like Congo or Nigeria—the country would simply remain what it is, the Afghanistan of today, and that’s more than bad enough.

So the international community continues to hope for the best. At the Kabul International Conference on Afghanistan in July, officials from sixty countries took turns pledging to redouble their long-haul support—military, economic, and political—to Karzai’s government. Signatories of the communiqué presented at the conference agreed to funnel fifty percent of future aid directly through Afghan ministries, and to recognize “the leadership and ownership of the Afghan Government, underpinned by its unique and irreplaceable knowledge of its own culture and people.” But unless Afghans make a decision to help themselves too—to stand equally against the Taliban insurgency and governmental corruption, and to invest in their shared future—the country’s minerals and all their shining promise could remain locked underground for another fifty years. Or another hundred million.