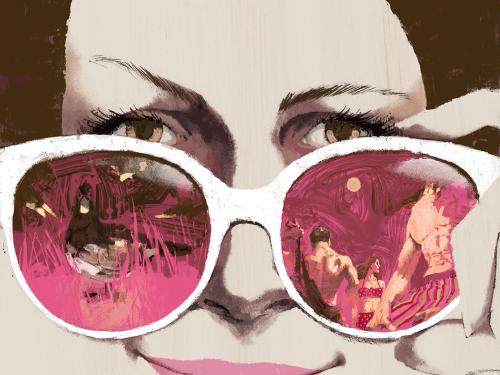

Zeritu’s Eucalyptus

After more than 2,000 climbs up Mount Entoto on the outskirts of Addis Ababa, Zeritu Zerga knew every step of the ascent. It began in the marketplace, where women set out pumpkins and avocados beside dresses, chat leaves, and jebena coffeepots along a road crowded with taxis and minibuses. Soon pavement changed to dirt, curving up and back, and back again, until Zeritu and her friends abandoned the road to cut uphill on a well-worn path. They entered the forest suddenly and completely as through a gate. In the shadows of the eucalyptus, the Ethiopian capital’s smoke and exhaust gave way to the scents of menthol and earth. Zeritu had miles to go before she could gather wood legally. She walked over bare forest floor, past guards leaning on trees or walking staves.

The guards were supposed to ensure that no one cut living eucalyptus, but they often levied “fines” even on properly gathered fallen deadwood. It was six hours before Zeritu passed them on her descent, now burdened by a bundle of firewood half her weight. She was fifteen, strong and energetic enough to use the grade to her advantage. The younger carriers kicked out almost playfully with each step, each kick bringing them further downslope. Zeritu was one of hundreds. When they filed back in the late afternoon, tourists in the market saw a scene that had been repeated for as long as people had cooked with wood.

For anyone who relies on an open fire to cook daily meals, the need for fuel rivals that for food itself. Staples from wheat to potatoes are inedible without cooking, while other foods require heat to release their greatest nutritional value. Save for raw foodists (who generally rely on the wide-ranging food choices of the modern world), human life requires cooking, which means having access to fuel.

Though the task of gathering fuel is an ancient one, the Addis Ababa market and the eucalyptus trees are both relatively new. In fact, their genesis can be dated to the day in 1886 when Queen Taytu Bitul stood on slopes draped with juniper, acacia, and kosso trees, looked down on the watered valley below, and declared that a city would bloom there. Addis ababa: a new flower.

Zeritu’s path threaded past the magnificent mountain church of Entoto Maryam, site of the feast that Queen Taytu held to commemorate Addis Ababa’s founding. According to historian of African agriculture and foodways James McCann, for four days tej honey wine flowed “like rivers,” and the aroma of some 5,000 roasting beasts brought “faintness to the heart.”

At the feast, the most irreplaceable smell and flavor of all was that of injera, the sour, platter-wide pancake common to royal and humble tables. The injera baked and steamed under the domed covers of innumerable mitads (clay griddles), constantly replenishing some 500 wicker baskets to overflowing. Then, as now, Ethiopians ate with their hands, and every bite, whether of humble chickpea sauce or chicken spiced with the secret royal berbere blend of peppers, was lifted to a hungry mouth within a folded pinch of injera.

As the capital grew, the amount of firewood used at spectacular state dinners was dwarfed by that used in the cone-shaped, thatched-roof, mud tukul huts of the commoners. Soon the receding forest represented a true crisis, for the slowly, evenly heating clay that makes a mitad perfectly suited for baking injera also gives it a voracious appetite for firewood. The forests of Entoto were vanishing into Addis Ababa’s hearths so rapidly that Queen Taytu’s husband, King Menelik, considered moving the capital west, to the more wooded Addis Alem. Only the introduction of Australia’s fast-growing eucalyptus saved the city from abandonment by Ethiopia’s political elite.

By the time Zeritu first went into the forest a century later, the juniper and acacia were long gone. The eucalyptus had been cut and regrown, then cut and regrown again, so that coppices sprouted like fistfuls of whips from what had once been single trunks. In an attempt to break the cycle of cutting and burning even degraded second growth, new laws restricted the carriers to gathering deadfall. Eucalyptus sheds enough branches, bladed leaves, and snakeskin-like bark to choke out undergrowth. But the carriers soon picked over the ground so diligently that the forest floor appeared raked, even swept.

On her way to find leaves and limbs, Zeritu walked over woodland earth bare save for an eerie webbing of roots. The wood she gathered was too small to split—just twigs and branches that she bound into a rough cylinder. Before hoisting the bundle on her back for the long descent down the treacherous slopes, she padded the outside with leaves. Like the other carriers, Zeritu wore the kind of inexpensive, open-toed, nearly treadless plastic sandals heaped for sale in yellow- or plum-colored piles on Addis street corners. Where fuelwood could still be found, there were leaves in slick mats, and carriers often fell. A short slide could easily become a tumble under a bundle’s weight.

The last time she climbed Entoto as a carrier, Zeritu came home empty-handed. She’d gathered her load, bound it, and set it on her shoulders when a guard confronted her. The slope was steep enough that her head scarcely reached to his waist; he stood over her, demanding a fine for the wood he claimed she’d cut. Zeritu refused to pay. Before she could turn, he struck her with his staff, beating her about the legs.

As the guard wound back for another blow, she reached over her shoulders with both arms, leaning forward to half-drop, half-hurl the wood into his chest. The weight was enough to bring him down and, for the moment, to pin him there. Zeritu fell backward. She tumbled down the slope, falling for once without wood, sliding down, and down, and down on leaves.

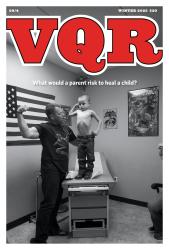

Black Onions, Sweet Rice

Renowned physicist and engineer Ashok Gadgil sat before his Berkeley, California, office’s wide, fogged window, remembering roasted onions. When he was a boy in central Mumbai, Gadgil’s parents cooked with piped gas; his uncle, who lived in the suburbs a twenty-minute train ride away, cooked with charcoal. That simple difference made his uncle’s house an exotic culinary world. “At my uncle’s house the favorite thing to eat was a fresh onion, cooked with charcoal,” Gadgil says. “Buried in charcoal.” The onions were charred on the outside, juicy within—and never, Gadgil remembers more than four decades later, dry.

Now director of the Lawrence Berkeley National Lab’s Environmental Energy Technologies division, Gadgil is a charming, balding, spectacled man of sixty-two. When he was a boy, food was changing across India, especially in urban centers such as Mumbai. Charcoal that had already supplanted wood-fired mud stoves gave way to canisters of liquid petroleum gas and finally to piped natural gas. Some elderly people complained about the changes: The onions weren’t smoky enough with gas; the new tin pans had hotspots and couldn’t give the slow, even simmering needed to blend rice and milk into sweet basundi. For that, one needed thick cast iron. Sometimes the elderly didn’t recognize the food of their youth. If it didn’t have the same flavor, Gadgil says, it simply wasn’t the same food.

In 2005, Gadgil traveled to Darfur with Environmental Energy Technologies division engineer Christina Galitsky in hopes of instigating a change in the cooking of western Sudan like the one he’d experienced growing up in Mumbai. When he landed in Khartoum, though, he wasn’t thinking of roasted onions or basundi; that would come later, as he began to reflect on the assumptions that shaped his work. He wasn’t thinking about Ethiopian injera or Sudanese sorghum or the millet porridge known as assida (also spelled aceda). When he landed, Gadgil was thinking about rape.

In November 2004, Chuck Setchell of USAID’s Office for Foreign Disaster Relief had approached Gadgil about developing a solid fuel for the stoves used in camps for Darfur’s internally displaced persons, or IDPs (the term refugee is properly reserved for people who have fled across international borders). The IDP and refugee crisis was worsening on the African Horn; Ethiopia was virtually ringed by camps for refugees from Somalia, Eritrea, Kenya, and of course Sudan. For the IDPs, Setchell said, one need in particular was as essential as it was seemingly pedestrian. Many of them lacked the fuel necessary to cook.

The Sahel—the band of ancient, dried salt sea that runs from Eritrea and the Indian Ocean to Senegal and the Atlantic—has always been relatively poor in wood. Under normal conditions, gathering fuel for daily meals can easily become a woman’s primary task in rural Africa. When attacks by janjaweed militias forced tens of thousands of people into camps on land that might once have supported one-fifth as many people, trees and brush gave way before newly arrived cooks as thoroughly as grass before locusts. By 2008, some women were walking as many as forty-five miles; a UN report referred almost wistfully to when the women had to travel a “mere” fifteen kilometers (9.3 miles) round-trip to gather a few days’ worth of fuel.

The paucity of wood sent women farther and farther out—seven hours, eight hours, ten, until some were “walking through the night” on sojourns that took them from home for nearly twenty-four hours. Such journeys took time and energy they couldn’t spare. Even in as relatively stable a nation as Ethiopia, fuelwood carriers like Zeritu—women far from home, traveling predictable paths—are always vulnerable to attack. In Darfur, female IDPs walked through land controlled by some of the militia who had driven them to the camps: Assaults, rapes, and mutilations were common enough that local aid workers used the shorthand phrase “firewood rape” rather than describe a given assault. There, rape was an act of war.

Though best known for his work on using coated coal ash in the large-scale purification of drinking water, Gadgil readily agreed to at least temporarily shift his focus from water to fire. He joined an informal but worldwide movement that would lead in 2009 to the UN’s Global Alliance for Clean Cookstoves (GACC) calling for 100 million improved cookstoves worldwide. It was a goal commensurate with the scale of the problem; even 100 million stoves would reach only 10 percent of the billion women who cook over solid fuels (perhaps 3 billion people in all rely on them for daily meals). Such massive numbers encouraged large-scale efforts to deploy mass-produced, relatively generic stoves that could burn fuels from coal to dried dung to jatropa seed.

But the grand diversity of human cooking also points toward an alternative approach that begins with local food rather than engineering efficiency, an approach born of respecting desires as well as needs—flavors as well as nutrition. Though smaller scale, and sometimes frustratingly slow, it’s one that suited Gadgil’s temperament and personal history. His first step toward it came after two months of research, when he concluded that the basic concept for the Darfur stove was fundamentally flawed; Sudanese simply didn’t have the right kind of kitchen waste to produce fuel pellets.

“It would be things like banana peels, the core of a cabbage. Stuff like that,” he recalls. Unfortunately, such green matter is mostly water. “Seventy-five, eighty-five percent is water. So if you dry it you get very little dry biomass.” Sometimes women would try to cook over stalks from sorghum gathered from the fields surrounding nearby towns. But as Gadgil points out, what Americans might see as waste is, to a subsistence farmer, “actually straw. And that is used for thatching, and that is used for walls, and that is used for fences. There is no refuse. Everything is put to some use. And for somebody to come into the fields and just take it … they’d be beaten so badly that it was unthinkable.”

On hour-long drives to a temporary lecturing position at Stanford, Gadgil often found himself fixating on the fact that the camps’ already tenuous security was often undone by the need for wood. “That horrified me,” he said. He now knew his team couldn’t make fuel from Sudanese kitchen refuse. Importing liquid petroleum gas or other relatively clean fuels seemed impractical, given that it would rely on an uncertain supply chain. For years to come, female IDPs would have to rely on firewood: the same fuel that generations of Darfurian women had burned on three-stone fires.

The Beast in the Hearth

A three-stone fire is exactly that: three stones arranged as a rough but stable tripod around a flat central hearth. Whether the “stones” are genuine rocks or substitutes—bricks, cans, hubcaps, humps of mud—the three-stone fire is one of humanity’s fundamental creations. Richard Wrangham argues in Catching Fire: How Cooking Made Us Human (2009) that it is the fundamental creation, with the food cooked on it providing the nutrition necessary for the brain to have evolved into its modern form. The three-stone fire remains nearly universal among the 3 billion people who rely on solid biomass fuels like firewood, charcoal, and dung. Even where it has been abandoned, its shadow often remains in the form of a three-sided mud stove or three-legged incense burner.

Still, the three-stone fire is hellishly inefficient, transferring as little as 10 percent of the heat it produces to a pot and the food it holds. To a cook accustomed to using electricity or gas, inefficiency connotes taking a few more minutes to boil water or a slightly higher power bill; for a fire cook, inefficiency means hours of gathering wood or pressing dung on a wall to dry. It means burning five pounds of wood to make one pound of charcoal and walking farther to reach fewer trees.

The problems that begin with the need for fuel continue when the fuel is burned. The GACC’s call for 100 million stoves was some thirty years in the making, beginning in the 1970s when environmental activists recognized that the open hearth’s demand for wood or charcoal was a major driver of deforestation. A decade later, University of California, Berkeley professor Kirk Smith monitored shocking concentrations of carbon monoxide and airborne particles in homes relying on solid fuels, concentrations now thought to kill some 2 million women and children every year (according to the US Environmental Protection Agency, indoor smoke can raise the particulate matter in a hut to 3,000 micrograms per meter, as compared to thirty in downtown Berlin). Burns caused by open flames add hundreds of thousands more deaths. Deforestation, indoor air pollution, and burns have been joined by worries about black carbon, which settles on Arctic snows, absorbs heat, and melts ice, making it second only to carbon dioxide as a cause of global warming. The range of problems associated with three-stone hearths is vast and testifies to the hearth’s central place in human life.

These interconnected problems also complicate solutions, since an “improved” stove may be effective at addressing one issue while doing nothing to solve another. For example, adding a chimney can improve indoor air quality without reducing the amount of fuel burned. An efficient stove that saves on fuel can still be unstable, even prone to setting accidental blazes. Enclosing a flame in a ventilated cement cylinder can stop children from falling into the embers, while the smoke that fogs their eyes and lungs continues to flow.

Even with all the critical technical parameters of stove design, Gadgil believed that the first thing a designer should consider was the culture of the cooks themselves. He was far from alone in this, of course; the question of how highly to prioritize cultural and culinary desires had been raised for decades. When the first, idealistic designers began work (the Aprovecho sustainability research collective in Cottage Grove, Oregon, was one early focal point), they assumed that in conditions of dire poverty cooks would be so eager to adopt a wood-saving stove that they’d willingly change the way they cooked. But that assumption often proved flatly wrong. As Aprovecho’s executive director Dean Still readily conceded in a 2009 New Yorker profile of the institute’s work, “the world is absolutely littered with failed stoves.”

People have deep attachment to their most basic foods, even in crisis situations—perhaps in crisis situations most of all. “For displaced populations who have lost everything, including family members murdered before their eyes,” Gadgil says, “one of the things they would like to hang onto, the last thing they would hang on to, is their traditional food. So it is very difficult to go and tell people, suddenly, even in a famine situation—I’m talking about Indian famines, I’m talking about fifties and sixties famines—you can’t go into famines and say, ‘Oh, you stop eating rice, because Americans have sent wheat, here is American wheat.’ ”The thought makes him laugh. “ ‘Start making rotis now.’ They would starve!”

Indeed, prior attempts by aid organizations to ease the burdens of cooking in Darfur had involved the free distribution of modern, machine-made aluminum pots that many Sudanese considered useless. “Women would use them for storing water, or sometimes to hold twigs,” Gadgil says. “Never to cook.” He arrived in Sudan with an efficient Indian-made cookstove known as the Tara, a fine example of the rocket stoves modeled after Larry Winiarski’s Aprovecho designs. But for the Tara to avoid the fate of the other failed stoves and abandoned pots, it would have to do more than reduce smoke or guard against burns. The great imperative in Darfur was to cut the amount of time women spent beyond the camp perimeters—and that meant reducing the amount of wood needed to prepare traditional Sudanese foods. Changing the mechanics of cooking began with learning how to cook.

Sorghum Is Life

When Gadgil approached the camp near Kalma, Sudan, the sky was an extraordinary blue, the air clear save for light-brown dust billowing behind the car. Hard sun beat on scrubby trees and brush, then gave way to stumps. A white line appeared on the horizon, thin as a streak from a fine pen. Soon the stumps vanished, and there was nothing but bare and beaten ground. Across that expanse the white line swelled until at last resolving into the earthen brick wall and pale torn tarps of Kalma Camp.

Some of its almost 90,000 people had been there for three years.

Much of what Gadgil and Galitsky would learn in the coming weeks depended on his ability to connect with the men and women, an ability that his colleague, Dr. Kayje Booker, recalled from their later time in Ethiopia with deep affection. “We’d go into houses and he’d make these long speeches, telling them about our journey and how honored we were to enter their homes, and it seemed like too much to me,” she says. “But they really appreciated it—it meant a lot that we were respecting their hospitality.” Still, when it came to gathering essential data about cooking, Gadgil functioned as something of a decoy, talking with the camp’s (invariably male) leadership while Galitsky interviewed the women whose skills and opinions were truly needed.

What stayed with Gadgil longest were the women who did approach him, hands outstretched and palms toward the sky. “I was puzzled about what I was supposed to see. But through the translator I understood that they were asking me to touch their hands, to feel how scarred and rough they were. They’re going out there and hacking away at desert wood, this thorny brush, and they’re walking seven hours in the sun. And what they were trying to convey to me was the coarseness of their lives.”

The food the women were laboring over was a porridge served with a topping of sauce. It seemed simple enough, not unlike African staples from Kenyan maize (ugali) to Nigerian yam (fufu) to Ugandan plaintain (matoke). But such simplicity can be deceptive, masking a deep cultural—and hence personal—commitment to the way a given food should be prepared. Staple dishes are tenacious enough so as to have been carried to the United States as, among other dishes, gumbo served over rice (gombo is the Bantu word for okra). Cooking techniques are often as stubborn as the foods themselves.

In Sudan, the primary staple is a fermented assida porridge topped with one of dozens of mulah sauces. The assida itself can be made from millet or cassava root, but it is most often sorghum, an ancient crop that originated as a wild grass somewhere between Lake Chad and the high Ethiopian escarpment. Assida has long been cherished, so that Darfur’s eponymous Fur tribe serves it from beautiful ceremonial hardwood gadah bowls perched on wickerwork supports. Unsurprisingly for a crop worthy of being named aish, or “life,” and vitally from a stove-design perspective, assida forms the irreplaceable center of a vast web of language, culture, history, ecology, and taste.

Replacing assida would have meant replacing the basis for much of what gave life shape and meaning before the camps. Gadgil didn’t intend to try. In fact, the subtleties of assida’s central place in Sudanese culture meant less to him than did the simple fact of it. To design a stove that Sudanese women would use, what he needed to know about assida was how to make the porridge that had been milled locally for some 10,000 years.

“From the start I knew we had to worry about fitting the stove upstream to the pot, and the pot to the food,” he told me. “And downstream to the fuel, and the fuel to the cooking style.” It was a systemic approach that began with attention to the ways that the Sudanese cooked.

The broad contours of cooking assida are straightforward. The cook—in rural Africa, most often a woman—mixes ground sorghum into a ball, then leaves it overnight to ferment. In the morning she adds the ajin dough ball to boiling water bit by bit, stirring until it disperses and thickens into true assida. Though it looks no more complex than boiling pasta, every step has nuances important to Sudanese cooks.

The rounded bottoms of tajin pots—a two-piece clay pot with a cone-shaped top to seal in steam and heat—are ideal for setting snugly within three imperfectly spaced stones. Many of the women cook standing up; others cook kneeling but upright, hips over their knees, using leverage as they stir the pot (under less fraught circumstances, many might have sat on stools). Each stirs with a malud, a wooden, three-foot-long, harpoon-shaped implement ideal for alternately slicing through the thickening mixture and scraping it from the pot’s sides. They adjust heat by removing or replacing the pot, a process of constant watchfulness and work that urban or more prosperous cooks have replaced with the simple turning of a knob. Significantly, most cook alone.

The result, if all goes well, is a stiff, viscous porridge—the key word being stiff. McCann suggests that, when it comes to properly cooking starchy African staples such as fufu or matoke, texture is often more important than flavor (the separate grains produced by steaming rice are an example). Carelessness or improper equipment can lead to more than a dozen precisely defined textural defects in assida, any of which render it scarcely worthy of being called food: Assida titgallum breaks into big chunks instead of along fine lines; assida-nay-ya is half-cooked and thought to cause bloating; wileidat refers to a different manner of half-cooking, leaving small, encased nodules (the name translates as children). There’s a name for burnt crust, another for when burnt crust breaks up.

Such flaws are prevented by stirring—constant, vigorous stirring. The kind of stirring that would knock over any pot resting on a base less solid than three robust stones—which explains why local cooks rejected the Tara stove. As Gadgil soon saw, the Tara was relatively flimsy and unstable; its firebox suffered in the high winds typical of the Sahel. The biggest problem by far, though, was that it held only flat-bottomed, cylindrical pots, with right angles that invariably produced chunky assida titgallum, half-raw assida-nay-ya, or the mischievous nodules of wileidat. A proper tajin or tungutungus pot, with a round bottom that a cook could scrape clear of thickening porridge, would perch atop the Tara like a crown as heat escaped from every side.

The Tara stove did have its merits. Under narrow conditions, it provided a clean and efficient burn. What Gadgil had to do was make it Sudanese.

To Fry Onions

The original 2006 report by Gadgil’s team (for which Galitsky served as lead author) contained an unemotional portrait of a hostile landscape. “There is no fuelwood left in North Darfur at all,” it noted flatly. Even the rootballs had been dug up. In South Darfur, some of the remaining and increasingly remote wood was actually dangerous—ouder smoke, the report warned, could cause blindness.

Two years later, a second report described the team’s attempt to mimic the preparation of Sudanese staples in formulas dubbed the “Mulah and Assida Test Protocols,” performed both “with and without wind.” The testing for assida, while crucial, was relatively uncomplicated. The standard procedure in stove design is to perform a series of simple Water-Boiling Tests (WBT), followed by Controlled Cooking Tests (CCT) of local foods in the lab, and finally Kitchen Performance Tests (KPT) by potential users in the field. But as long as the stove was stable enough to withstand vigorous stirring, they could skip the CCT for assida entirely, with the tungutungus pot standing in for Sudanese cooking preferences.

The test for mulah, which has much more flexible ingredients (Sudanese food expert Hamid A. Dirar concedes that even his list of fifty versions is far from exhaustive) was considerably more intricate. Gadgil’s group settled on one made of onions fried in oil, perhaps the most basic of all mulahs—and one that resonated strikingly, if still unconsciously, with the changes he’d seen to his favorite childhood foods.

Fried onions are so simple that the name seems to provide the recipe: To make fried onions, fry onions. Nevertheless, like many basic ingredients, they reward attention to detail. When caramelizing a pot of “big, dusty” sliced specimens, chef Tamar Adler writes, “the whole mess will look soggy and unconvincing until right before the onions are done, at which point they melt completely into a golden jam and all their sugars come out to toast.” Darfurian cooks are as discerning as any about what being cooked right means.

Appropriately, then, the Mulah Test Protocol could compete with the most exacting gourmet recipe, running for four full pages varying between the technical and nearly homey. Specifics about the placement of anenometers to gauge the wind, and the size to which both onions and wood should be cut, were followed by a note that “previously chopped onions may be drier than freshly chopped onions, and hence require less heat to fry.” Later came the admonition to cook to precisely 248 degrees Fahrenheit rather than simply to the point of first browning. There was as much attention to the food in the pot as to the stove and the amount of wood it consumed.

For months, a corner of the lab complex that saw the discovery of elements from Berkelium to Californium served as an improvised Sudanese kitchen. Hundreds of preparations later, the Tara had evolved into the Berkeley-Darfur Stove, or BDS. Each of the many changes came only after multiple, painstaking iterations. An upper heat shield was replaced by sunken supports that held the pot firmly within the stove body. The stability necessary for women to cook alone could have come from horizontal rods, a tripod fixed to the upper rim, or a system of brackets, but instead came from stakes calibrated to hold the body in place in loose Sahel sands. The wind was channeled through offset holes, feeding oxygen to the fire without whisking away valuable heat. Even changing the body from a simple cylinder to an octagon allowed for easier assembly (albeit with specialized tools), thus employing local men in a process that would otherwise necessarily take place in—of all places—Mumbai. Together, the modifications added up to possibly the first assida-specific cooking utensil since the tungutungus.

Today, distribution of the stoves is handled by Potential Energy, an NGO founded as the “Darfur Stoves Project.” Under executive director Andrée Sosler, Potential Energy has amassed a proven track record of adoption, training, and—crucially, given the long history of quick adoption followed by just-as-rapid abandonment—continued use, with Sosler overseeing the sale of more than 32,000 stoves. Admittedly, when measured against the worldwide need for a billion stoves, this number might seem discouragingly modest. But meeting the enormous global need may well demand hundreds of designs as well-targeted (and hence localized) as the BDS; the respect demonstrated by the design seems to have helped develop a real attachment with the users, who have dubbed the BDS the kanun khamsa dagaig, or “five-minute stove.” The durability of the BDS—and its use to cook the food eaten by nearly 200,000 Sudanese refugees—is an undeniable bright spot. “They sleep with the stoves,” Gadgil says. “A woman will bring the stove in from the kitchen and set it beside her bed for safekeeping.” He takes understandable pride in this story.

Still, there’s uncertainty about how much the BDS reduces the sexual violence that compelled its creation. Though the 2008 report claimed that the stove could cut risk of assault by three-fourths, firewood rape will continue as long as women have to spend entire days on treks in search of fuel. And, as the Women’s Refugee Commission’s Erin Patrick points out, rape is chronically underreported, even in countries with a firm legal commitment to a victim’s privacy and rights. In Sudan, rape leaves women vulnerable to divorce, abandonment for “adultery,” even arrest. Understandably, rates of reporting even to health officials are far lower than in the US, and to law enforcement lower still.

That reticence is one reason that Potential Energy gauges success in Darfur not by documented decreases in rape but by the seemingly sterile measure of increased household income. Gadgil still hopes that lowering demand for firewood might reduce sexual assault by making wood carted in by nomads affordable to women who would no longer have to leave the camp at all. Sexual violence is just one aspect of the oppression of the region’s women, which might be somewhat ameliorated by reducing the work it takes to feed a family. By cutting back on the need to collect or buy fuel, the BDS can save its users about a dollar a day—which allows them to afford vegetables, fruits, even dried meat to fry as part of mulah. Extra income can mean better education for children and less time spent in wood smoke.

From this perspective, the BDS—like other efficient stoves around the world—is more than an emergency intervention. Such stoves become part of the worldwide movement for gender equality that journalists Nicholas Kristof and Sheryl WuDunn call the most promising means of fighting global poverty. Having a choice of how to use time is a necessary, albeit not sufficient, condition for improvements in daily life, and the success of the BDS in both the lab and the camps showed real potential to help increase women’s opportunities on a larger scale.

Where could the lessons—and a modification of the existing stove—best be applied? Mongolia, where burning coal made Ulaanbataar the world’s most polluted city, seemed a good possibility, as did earthquake-struck Haiti. In the end, though, Sosler and Potential Energy settled upon Zeritu’s homeland of Ethiopia, Sudan’s neighbor to the east. According to the World Health Organization, more than 95 percent of Ethiopia’s approximately 90 million people depend on wood and other solid cooking fuels, much of it procured during three-hour daily searches that rank among the longest in sub-Saharan Africa. What’s more, the government was already committed as a working partner to the GACC. A Berkeley-Ethiopia Stove might help to improve health and opportunities for tens of millions of women who struggle against deep poverty without suffering the catastrophe of displacement.

Designing the BDS had been painstaking and laborious and had at times involved a substantial degree of personal risk for Gadgil and his field team; its success hinged on maintaining a delicate balance between engineering precision and respect for Sudanese cooking. Still, when compared to the challenge of modifying the cooking of a nation as large and diverse as Ethiopia, creating a stove to reduce wood use in IDP camps could be seen as almost straightforward. In the camps, the severe limitations on life that made intervention urgent also limited the range of needs that had to be met. Gadgil’s team didn’t have to concern itself with the refined flour breads of the cities or the milk and meat of the nomadic Nuer. Groups like the Fur and Dinka might have their physical and linguistic differences, but they also, Gadgil says with relief, “had very similar food, and very similar pots. Thank goodness!”

Ethiopia’s cooking has roots among both Oromo nomads and the imperial dynasties claiming descent from Solomon and the Queen of Sheba. The various flavors of the country’s dishes come from the farming of Africa’s highlands as well as the spice routes of the Indian Ocean and the Red Sea. Its breads are baked by people speaking more than twenty indigenous languages, whose pancakes or loaves might be made from wheat or millet, teff or the core of an ensete (false banana tree). Ethiopia’s is a firewood-hungry cuisine that also maintains great respect for raw dishes like the Gurage kitfo of chopped beef, clarified butter, and spice. To further complicate matters, many of the country’s neediest cooks are not native Ethiopians, but refugees in decades-old camps that ring the borders like fortifications.

The BDS’s success in Sudan was built on deep respect for local cooks. Still, the same attention to cultural minutiae that made the stove perfect for Darfur also raised the possibility of failure when it was introduced elsewhere, even in a neighboring country. Success would depend on learning, once more, what it meant to cook a meal.

Three Meals

When performed in Zewde Eshetu’s small, traditional tukul house on the outskirts of the northern Ethiopian town of Lalibela, the traditional Ethiopian coffee ceremony is a social occasion filled with conversation and caffeine. Long before the first cup pours from a jebena’s elegant, jet-black spout, though, the ceremony has remade the tukul by filling it from the earthen floor to thatching with smoke layered upon smoke.

First comes smoke from a stove fueled by eucalyptus charcoal. Charcoal requires hideous numbers of trees; 100 pounds of wood produces one-fifth as much charcoal, which keeps the higher hills bare and constantly eroding. Still, charcoal makes much less smoke than firewood; Zewde considers it essential for a proper ceremony and buys it in small sacks at the local market.

But the persistent and unhealthy charcoal smoke is quickly overwhelmed by smoke that would be part of the ceremony even if performed over an electric stove. Much of it comes from roasting coffee, as Zewde stirs raw beans with a slender stick until they’re charred and black. As popcorn bursts on a second stove (an accepted substitute for more expensive toasted sorghum, popcorn is part of every complete coffee ceremony), Zewde shares the smoke with her guests, blowing from the roasting pan and over their faces as gently as a blessing. Meanwhile, what look like quartz pebbles smolder in a dish, the slow combustion of hardened etan sap soon fogging the eucalyptus rafters nearly from sight. The etan’s sweetness, the smell of popcorn, the coffee both roasting and boiling, charcoal in two stoves—even in full knowledge of what the smoke can do to Zewde, the scents so enliven the tukul that the first, heavily sugared cup of coffee seems nearly superfluous.

Coffee is undoubtedly the most widely beloved of the crops that led Soviet botanist Nikolai Vavilov to declare Ethiopia one of the planet’s great sources of agricultural biodiversity. Ceremonies like Zewde’s are often thrice-daily—nine cups!—events. Potential Energy associate director Debra Stein remembers with a laugh that during her first trip to the country the constant stream of coffee kept her up until three every morning. Unsurprisingly, she and Sosler quickly recognized that making coffee is one of the three things an Ethiopian stove absolutely must be able to do.

The BDS was thus modified to accommodate a jebena by inserting a staggered triangle of rebar above the firebox. The fire itself prompted a moment of anxiety—seeing that most women in Addis Ababa made coffee with charcoal, and knowing that the combustion in a wood-burning Darfur stove was radically different, Stein confesses that she “got really nervous. I was like Oh, God, they really need to fix this!” Still, in a country as diverse as Ethiopia, it was already clear that they wouldn’t be able to address the needs of all cooks. Instead, they decided to focus on the truly rural cooks who depend almost exclusively on wood.

The BDS was better suited to preparing the second of the three essential Ethiopian dishes, the rudiments of which can be seen drying outside homes ranging from rural tukuls to the tan, stucco-plastered Addis Ababa Condominiums near the city’s namesake university. What mulah is to Sudan, wat is to Ethiopia—the essential daily sauce that tops the local staple grain, tuber, or legume. The most common variant in Ethiopia is made from shiro flour, and in the condominium courtyard the ingredients for shiro wat make a lovely, almost tiled tableau: yellow chickpeas and unpeeled purple garlic dry on a blue tarp, red peppers for berbere on a green. Shiro often begins from scratch even in middle-class households, the ingredients drying until ready to be ground into flour at a neighborhood miller.

Life in the condominiums is relatively free of smoke—at least unwanted smoke. When a resident such as Rahael performs a coffee ceremony, the etan is dense and, to a newcomer, nearly cloying. I joined her for coffee and learned that she wants smoke, relatively free of the carbon monoxide and black particulate given off by charcoal (let alone wood). When she cooks wat, though, there’s no smell but that of cooking food. Instead of Zewde’s two or even three simultaneous charcoal fires, Rahael uses a two-burner, stainless-steel, Swedish CleanCook stove, its bright-blue ethanol flame burning even more beautifully when you’ve seen the kind of smoke it has replaced.

The CleanCook is distributed by Project Gaia, a nonprofit dedicated to replacing open-fire cooking with ethanol stoves. It is perhaps the ideal stove for Ethiopian coffee and wat: compact, efficient, burning a biofuel made from discarded byproducts of sugar mills and modified to hold a jebena. Still, for many people, it remains aspirational. The unit is more expensive than a BDS, costing $50 against approximately $30, and the government commitment to ethanol as a gasoline additive makes its availability for cooking fuel uncertain. The CleanCook and BDS can thus be seen as complementary rather than competitive; until clean stoves are universally available there will always be a need for bridge units like the BDS: solid, thoughtfully crafted but ultimately insufficient stoves that make an immediate difference in women’s lives by burning less wood or charcoal.

As with mulah, cooking wat begins with onions. Ethiopian cuisine is sweet only rarely, to the point that cooks avoid caramelizing onions that give sauces body and texture. Some go so far as to cook the onions down with water rather than oil, using a rounded pot specifically intended to prevent the sugars in the onions from, as Adler put it, “coming out to toast.” They simmer more than saute, breaking down into a thick base. The ethanol CleanCook and the Berkeley-Ethiopia stove (once modified to accept the jebena’s rounded bottom) are well suited to prepare the onions, as well as the final preparation of shiro wat.

The biggest challenge is preparing injera to accompany the wat. Ideally, injera—the third essential dish, and the heart of Ethiopian cooking—is made from teff, a grain born, like coffee, of the region’s high elevations (many Ethiopian cooks believe that iron, one of the grain’s greatest health benefits, helps them to thrive in high altitudes). Like sorghum in Sudan, growing teff has shaped the agriculture—and hence the landscape—of the country it feeds. Every complete European meal may include bread; every complete Southeast Asian meal, rice. In Ethiopia, injera is often in every mouthful. Reassuring shiro wat, garlicky gomen collard greens, robust tibs—none of their flavors can be separated from the spongy, sour injera used to scoop them from platter to mouth. Made from a grain that was until recently cultivated only in Ethiopia, fermented to specific local standards, baked on a vessel specific to the region into a bread rather than a typical porridge, injera is a source of national identity.

The preparation of injera is beautiful to watch. The batter pours in a smooth spiral to cover a hot mitad; the batter bubbles, a product of the mitad’s evenly heated surface and of three days of fermentation. A stack of injera can verge on glorious: tasty, traditional, and healthful.

But when it’s cooked in an alley over eucalyptus, the smoke can be as ugly as injera is beautiful—ugly in the alley, ugly in the nose, ugly in the air. Whether purchased from a fuel-wood carrier or gathered from a construction site (the wood forms skeletal scaffoldings on half-completed buildings throughout the city), eucalyptus gives off black and acrid smoke, its menthol toxic. Such cooking may force a woman to rise before dawn to spare her neighbors the smoke, and to squat below the firebox for gulps of clean air. Meanwhile, the eucalyptus needed for firewood replaces native woodlands and chokes out habitat.

To say that a single stove could stem that process, while helping women cook in clean air—and, crucially, to spend less on fuel—would make for a satisfying story. The truth, though, is that preparing Ethiopian cuisine properly, in a way that Ethiopian cooks will accept, will always require more than one stove; cooks using either a BDS or a CleanCook could make only half of a given meal.

It’s a fact that Sosler and Stein readily concede. For proper injera, Stein says, “you have to get a very specific temperature, and it needs to be very evenly distributed.” If the bubbles, or “eyes,” don’t look right, “then just throw it out, or feed it to the animals or something. It’s very, very particular.” And, she adds, it’s not something the Berkeley-Ethiopia Stove is designed to do. Project Gaia’s highly successful distribution of CleanCook stoves in refugee camps bypassed the problem; recognizing that Somali injera (unlike the Ethiopian or Eritrean versions) was small enough to be prepared on an ethanol flame, they wisely concentrated their efforts where the single stove could meet all of a cook’s needs.

None of which means that the Berkeley-Ethiopia Stove (which is still undergoing active modification) is a failure or doomed to become one. In Sudan, respect for local cooking helped to design a single stove that could accommodate it. In Ethiopia, it might mean focusing on one discrete part of an enormously complex society—such as working to equip a particular economic class of women with a way to make shiro wat to accompany injera baked on the concrete Mirt stoves distributed by the German governmental agency GIZ. If the Berkeley-Ethiopia Stove can only reduce half of the fuel used to cook half of a typical meal, that reflects the reality of cooking—messy, complex, surprisingly stubborn. Indeed, the impossibility of modifying the BDS into an Ethiopian’s only stove supports Gadgil’s basic contention that changing the way people cook must start with culture, even with everyday pleasure.

A billion women cook over open fires. They need stoves for wood, stoves for charcoal, stoves for ethanol, stoves for countries and for cities, stoves for people who earn a dollar a day and people who earn three. Improving cooking in a way that increases women’s safety and opportunity also means attention to every aspect of a meal, from field to pot—including the effect of reforms on fuelwood carriers like Zeritu, who might, in a horrible irony, lose jobs dependent on ubiquitous three-stone fires.

Some fifteen years after her fight with the forest guard, Zeritu works for the Women’s Former Fuelwood Carriers Association. Her office is a flaking blue, her desk dominated by ancient computers and a Singer sewing machine. Above her a portrait of the Christ child feeding doves in a rose garden hangs beside a poster reading Break the Chains! in bright red Amharic and English lettering; the words are swarmed by chain links labeled Abduction, Assault, FGM. In soft Amharic—a language with the flow of a soft Arabic but the occasional hard snap of Zulu click-speak—she speaks of gratitude for years here under the eucalyptus rafters, working among the madaweria spinning wheels and horizontal, blue yeshema metria looms.

The most important thing she creates are co-ops that help other women to give up carrying wood. Since Zeritu’s last trip up Entoto, most changes for the women working there—and on Kofa, Yelki, and Karanyo, the city’s other forested slopes—have been for the worse. What was a four-mile walk is now nine. The carriers now walk far beyond the city, beyond even the wheat fields of the nearest Oromo homesteads. Zeritu waits for them outside of town, waylaying the returning columns.

Many are reluctant to abandon the only work they’ve ever had. Zeritu is persistent: She wants to tell them what a different kind of life she leads now. Her co-op, she says with wonder, has its own employees. She has a nine-year-old son, a five-year-old daughter, and another girl she’s adopting with her husband; they live in her old neighborhood but in a bigger house, closer to the pottery-makers. She still uses wood to bake injera, but she uses an improved Mirt stove that funnels more heat to the mitad, releasing less smoke into her home. Even better, she uses a CleanCook for everything else—coffee, wat, the spaghetti and rice her children love.

Zeritu knows what carrying wood means, and what it means to stop. Today she weaves and looks for women. One day, she hopes, some of them might work distributing ethanol canisters for Project Gaia, spreading clean fuel from home to home. For now there are always more trudging to market, hunched under wood as they seek out their customers, feeding some of the billion fires that burn between 3 billion stones.